Quality Policy

- 1.Facelabo strives to be a company that satisfies its clients by providing them with products and services to delight their customers.

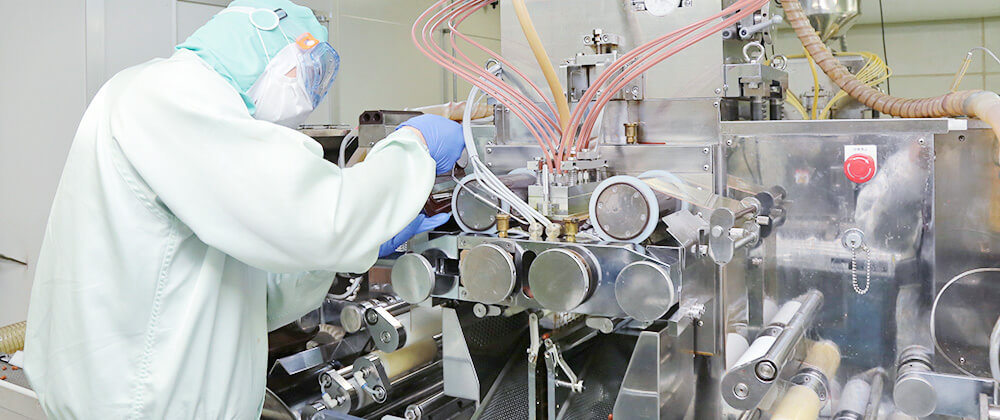

- 2.In accordance with the requirements of GMP (Good Manufacturing Practice), we are constantly improving our quality management system in line with our strategic direction.

Quality Management

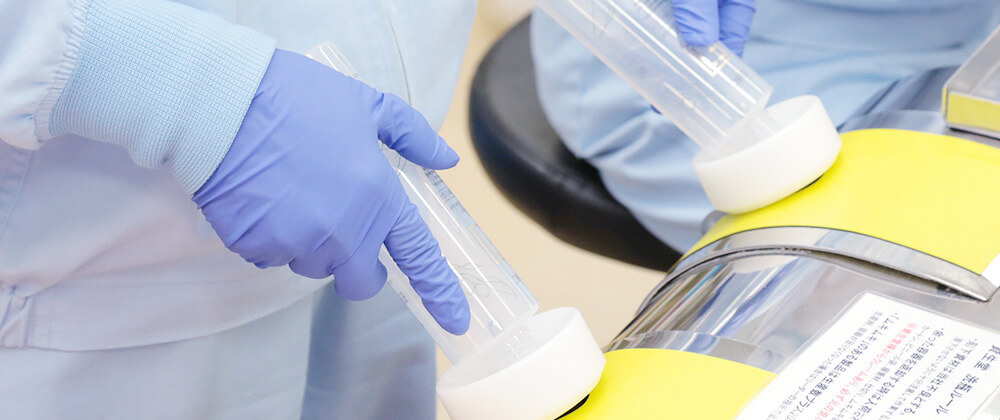

A Quality Management System That Meets International Standards

Facelabo has obtained ISO22716 accreditation for good manufacturing practices (GMP) for cosmetic products, and GMP for health supplements. The quality assurance we pledge to our clients is built on the foundation of our stringent management system.

As all Facelabo employees have a clear understanding of our corporate philosophy, “心技一体 (Integration of Spirit, Technique, and Technology),” and apply our customer-oriented quality management standards at all times, we make products that fully satisfy our clients.

-

ISO22716

(Cosmetic GMP) -

Health supplement GMP